Immersion Cooling Kit C2

From $1,580.00

12kW@35℃

Super cooling capacity

Tested in the Middle East by FogHashing Labs.

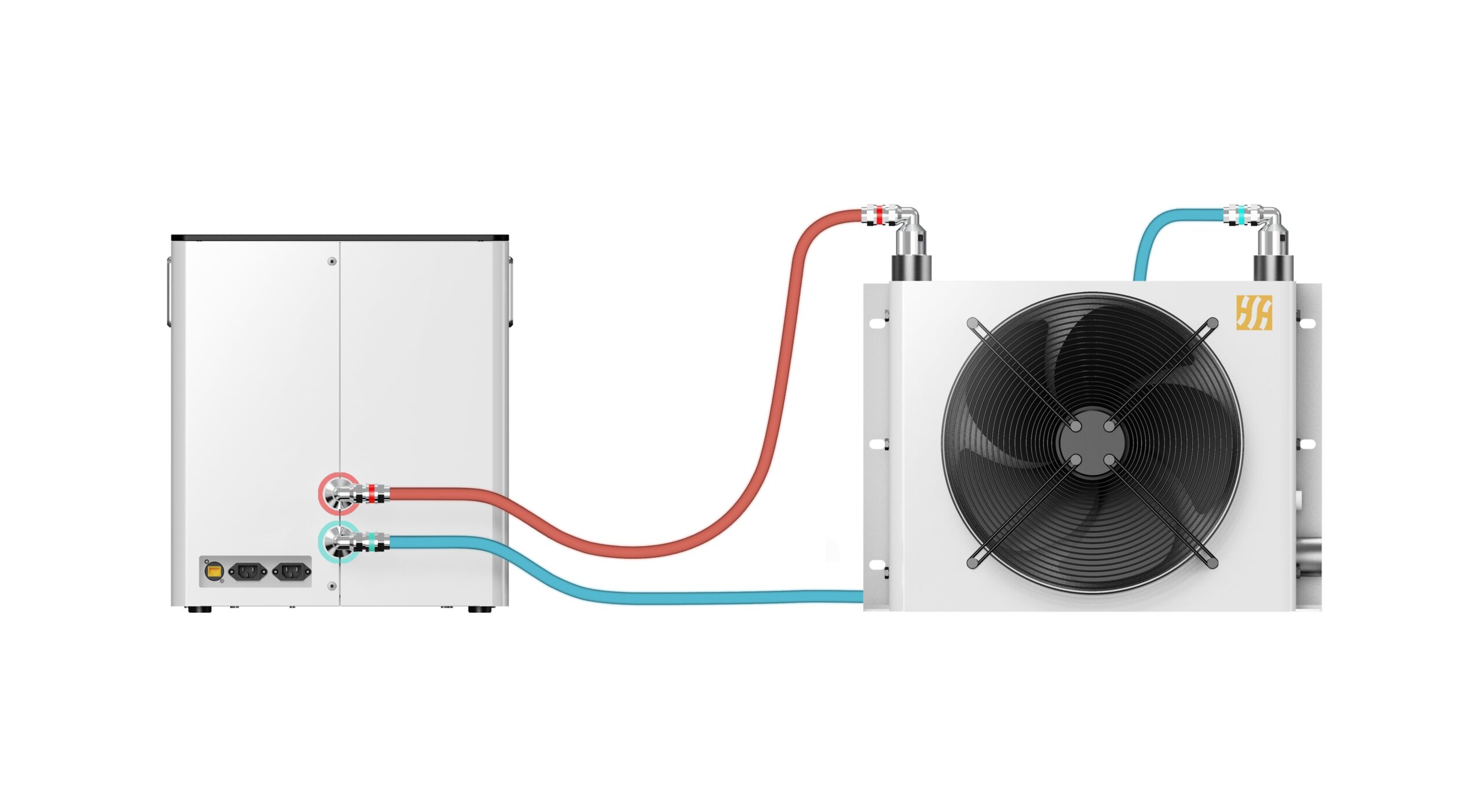

More Quiet & Energy saving Intelligent Speed Adjustment With EC Fan

Multi-mode switching&Supports heat recovery

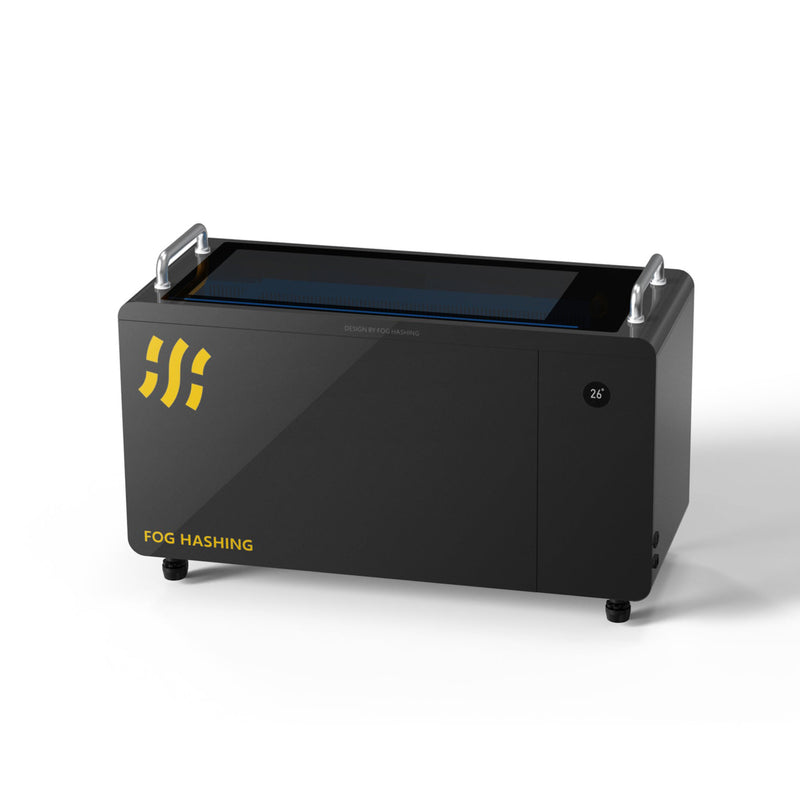

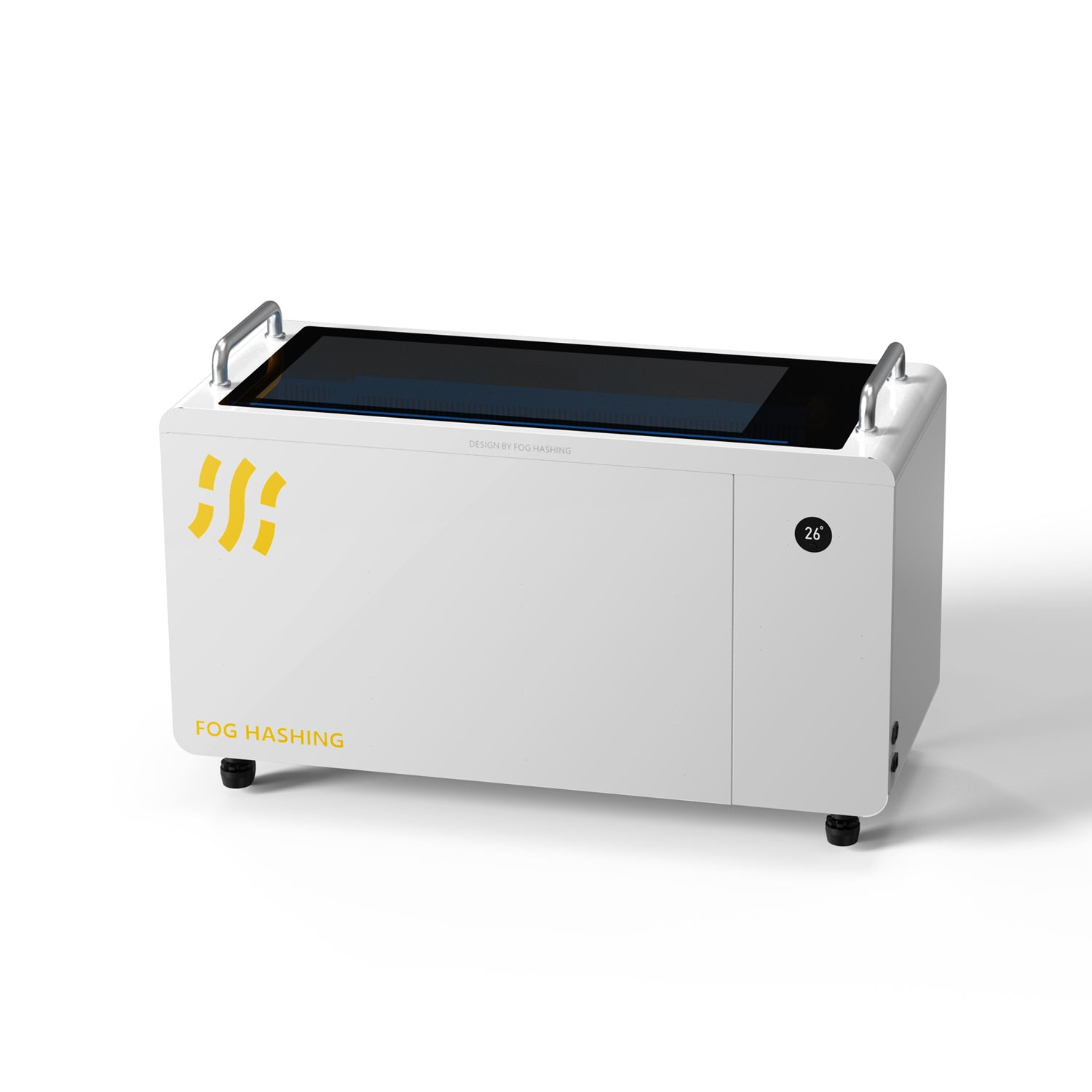

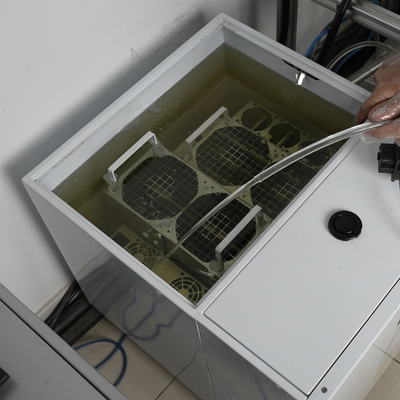

C2 TANK

Technical Specifications

Size

17.91(L)*20(W)*21.1(H)in

Inner Size

15.67(L)*11.73(W)*15.43(H)in

Coolant Volume

G.W

Intelligent Speed Tuning

Power

Display

Noise

Inlet/Outlet Temp

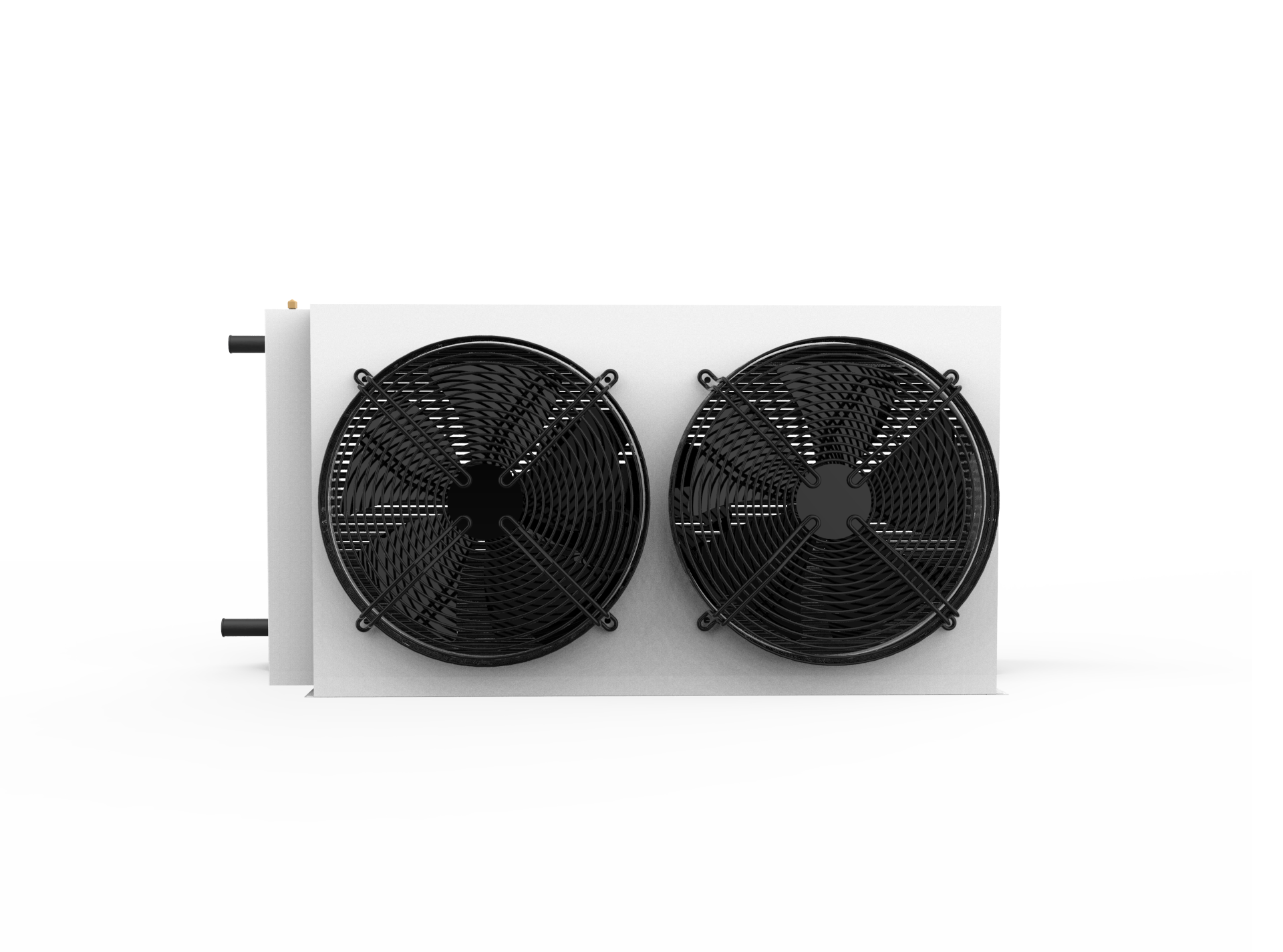

C2 Dry Cooler Technical Specifications

Size

42.36(L)*11.22(W)*20.9(H)in

Power

Input Voltage

G.W

Intelligent speed tuning

Cooling Capacity

Noise

Noise

EC Fan

2 pcs

Accessories

Product specification

Pipeline

Fan Simulator

4pcs

Oil Filling Pump

Miner Handle

4cs(Antminer)

Gasket

Sticker

User Manual

12V Power Adapter

FAQ

Electrical questions

What is the connection method of the C2 power supply?

The mining rigs in C2 is directly connected to the power supply or PDU at home, and the tank and dry cooler are connected through standard C13 connectors.

What is the connection method of the C2 power supply?

The mining rigs in C2 is directly connected to the power supply or PDU at home, and the tank and dry cooler are connected through standard C13 connectors.

What is the operating logic of the C2 fan? Can it be adjusted automatically?

Our C2 uses an EC fan to adjust the speed according to the temperature of the oil entering the tank (dry cooler oil temperature).There are 2 modes to choose (the mode is changed by a button inside the waterproof junction box outside the dry cooler).Press the button down is HEATING mode (waste heat utilization mode) 41.3℃ to start the dry cooler, 49.7℃ to maximize the dry cooler speed. Press the button up is NORMAL mode (normal operation mode), 20.5℃ to start the dry cooler, 28.9℃ to maximize the dry cooler speed.

How long is the pipeline for the C2 tank?

We provide two 5m pipeline as standard, and we also support customizing other lengths for a fee.

Will the tank automatically power on after a power outage?

Following a power outage, the tank is unable to initiate an automatic startup and necessitates manual activation by clicking on the screen.

Our C2 uses an EC fan to adjust the speed according to the temperature of the oil entering the tank (dry cooler oil temperature).There are 2 modes to choose (the mode is changed by a button inside the waterproof junction box outside the dry cooler).Press the button down is HEATING mode (waste heat utilization mode) 41.3℃ to start the dry cooler, 49.7℃ to maximize the dry cooler speed. Press the button up is NORMAL mode (normal operation mode), 20.5℃ to start the dry cooler, 28.9℃ to maximize the dry cooler speed.

What is the connection method of the C2 power supply?

The mining rigs in C2 is directly connected to the power supply or PDU at home, and the tank and dry cooler are connected through standard C13 connectors.

What is the operating logic of the C2 fan? Can it be adjusted automatically?

Our C2 uses an EC fan to adjust the speed according to the temperature of the oil entering the tank (dry cooler oil temperature).There are 2 modes to choose (the mode is changed by a button inside the waterproof junction box outside the dry cooler).Press the button down is HEATING mode (waste heat utilization mode) 41.3℃ to start the dry cooler, 49.7℃ to maximize the dry cooler speed. Press the button up is NORMAL mode (normal operation mode), 20.5℃ to start the dry cooler, 28.9℃ to maximize the dry cooler speed.

How long is the pipeline for the C2 tank?

We provide two 5m pipeline as standard, and we also support customizing other lengths for a fee.

Will the tank automatically power on after a power outage?

Following a power outage, the tank is unable to initiate an automatic startup and necessitates manual activation by clicking on the screen.

We provide two 5m pipeline as standard, and we also support customizing other lengths for a fee.

What is the connection method of the C2 power supply?

The mining rigs in C2 is directly connected to the power supply or PDU at home, and the tank and dry cooler are connected through standard C13 connectors.

What is the operating logic of the C2 fan? Can it be adjusted automatically?

Our C2 uses an EC fan to adjust the speed according to the temperature of the oil entering the tank (dry cooler oil temperature).There are 2 modes to choose (the mode is changed by a button inside the waterproof junction box outside the dry cooler).Press the button down is HEATING mode (waste heat utilization mode) 41.3℃ to start the dry cooler, 49.7℃ to maximize the dry cooler speed. Press the button up is NORMAL mode (normal operation mode), 20.5℃ to start the dry cooler, 28.9℃ to maximize the dry cooler speed.

How long is the pipeline for the C2 tank?

We provide two 5m pipeline as standard, and we also support customizing other lengths for a fee.

Will the tank automatically power on after a power outage?

Following a power outage, the tank is unable to initiate an automatic startup and necessitates manual activation by clicking on the screen.

Following a power outage, the tank is unable to initiate an automatic startup and necessitates manual activation by clicking on the screen.

Parameter questions

How noisy is the C2 system?

The C2 tank noise about 45dB, the dry cooler will reach 68dB(A) 10m at full speed.

What is the size of the C2 pump?

With an input voltage of 220V 50Hz, the pump has a power of 150W, and the maximum flow rate for circulating the Coolant is 36L/min, with a maximum head of 10m.

What is the C2 pipeline connector size?

C2 pipeline connector size is DN25 (External thread diameter Pipeline diameter 32mm).

After-sales questions

What should you do if there is high-frequency noise in the junction box when the fan is running at full speed?

In general, this issue might arise due to the loose fastening of screws on the internal PCB board of the junction box. You should dismantle the junction box and tighten the screws securely. If the screws cannot be tightened, you can try to replace the screws or add gaskets to tighten the screws (M3 screws and gaskets). If the problem persists, you can try to add gaskets (preferably rubber anti-vibration pads) at the bottom of the dry cooler to raise the fan to prevent noise caused by contact between the bottom of the dry cooler and the ground.

How to properly unload oil to avoid waste?

First, pump the oil out using the oil filling pump in the accessories. At the same time, there is an oil discharge port in the middle of the liquid separator plate at the bottom of the tank. After removing the screw, plug the oil filling pump in to clean up the liquid at the bottom of the liquid separator plate.

How does the oil filling pump work in accessories?

Instructions1. Connect the pump to the inlet and outlet pipes: Ensure a tight seal between the pipes and the pump to prevent low pressure or leakage. The arrow on the pump head indicates the direction of the outlet.2. Put the water inlet pipe below the coolant level, and put the water outlet pipe in the corresponding storage coolant receptacle.3. Connect the pump to the pump power adapter and then power on.

What is the material of C2 kit?

The material of C2 tank is cold-rolled steel , the dry cooler is copper and aluminum fins.

If the C2 pump stops or reports an error, what will happen?

If the pump stops working, a “Pump Error” prompt will appear on our Tank’s display screen, accompanied by an alarm sound. If this situation is not addressed, the temperature of the coolant will continue to rise due to the inability to dissipate heat. Eventually, this will trigger the temperature protection mechanism of the mining rigs, causing them to stop operating automatically.

In general, this issue might arise due to the loose fastening of screws on the internal PCB board of the junction box. You should dismantle the junction box and tighten the screws securely. If the screws cannot be tightened, you can try to replace the screws or add gaskets to tighten the screws (M3 screws and gaskets). If the problem persists, you can try to add gaskets (preferably rubber anti-vibration pads) at the bottom of the dry cooler to raise the fan to prevent noise caused by contact between the bottom of the dry cooler and the ground.

What should you do if there is high-frequency noise in the junction box when the fan is running at full speed?

In general, this issue might arise due to the loose fastening of screws on the internal PCB board of the junction box. You should dismantle the junction box and tighten the screws securely. If the screws cannot be tightened, you can try to replace the screws or add gaskets to tighten the screws (M3 screws and gaskets). If the problem persists, you can try to add gaskets (preferably rubber anti-vibration pads) at the bottom of the dry cooler to raise the fan to prevent noise caused by contact between the bottom of the dry cooler and the ground.

How to properly unload oil to avoid waste?

First, pump the oil out using the oil filling pump in the accessories. At the same time, there is an oil discharge port in the middle of the liquid separator plate at the bottom of the tank. After removing the screw, plug the oil filling pump in to clean up the liquid at the bottom of the liquid separator plate.

How does the oil filling pump work in accessories?

Instructions1. Connect the pump to the inlet and outlet pipes: Ensure a tight seal between the pipes and the pump to prevent low pressure or leakage. The arrow on the pump head indicates the direction of the outlet.2. Put the water inlet pipe below the coolant level, and put the water outlet pipe in the corresponding storage coolant receptacle.3. Connect the pump to the pump power adapter and then power on.

What is the material of C2 kit?

The material of C2 tank is cold-rolled steel , the dry cooler is copper and aluminum fins.

If the C2 pump stops or reports an error, what will happen?

If the pump stops working, a “Pump Error” prompt will appear on our Tank’s display screen, accompanied by an alarm sound. If this situation is not addressed, the temperature of the coolant will continue to rise due to the inability to dissipate heat. Eventually, this will trigger the temperature protection mechanism of the mining rigs, causing them to stop operating automatically.

First, pump the oil out using the oil filling pump in the accessories. At the same time, there is an oil discharge port in the middle of the liquid separator plate at the bottom of the tank. After removing the screw, plug the oil filling pump in to clean up the liquid at the bottom of the liquid separator plate.

How does the oil filling pump work in accessories?

Instructions1. Connect the pump to the inlet and outlet pipes: Ensure a tight seal between the pipes and the pump to prevent low pressure or leakage. The arrow on the pump head indicates the direction of the outlet.2. Put the water inlet pipe below the coolant level, and put the water outlet pipe in the corresponding storage coolant receptacle.3. Connect the pump to the pump power adapter and then power on.

What should you do if there is high-frequency noise in the junction box when the fan is running at full speed?

In general, this issue might arise due to the loose fastening of screws on the internal PCB board of the junction box. You should dismantle the junction box and tighten the screws securely. If the screws cannot be tightened, you can try to replace the screws or add gaskets to tighten the screws (M3 screws and gaskets). If the problem persists, you can try to add gaskets (preferably rubber anti-vibration pads) at the bottom of the dry cooler to raise the fan to prevent noise caused by contact between the bottom of the dry cooler and the ground.

How to properly unload oil to avoid waste?

First, pump the oil out using the oil filling pump in the accessories. At the same time, there is an oil discharge port in the middle of the liquid separator plate at the bottom of the tank. After removing the screw, plug the oil filling pump in to clean up the liquid at the bottom of the liquid separator plate.

How does the oil filling pump work in accessories?

Instructions1. Connect the pump to the inlet and outlet pipes: Ensure a tight seal between the pipes and the pump to prevent low pressure or leakage. The arrow on the pump head indicates the direction of the outlet.2. Put the water inlet pipe below the coolant level, and put the water outlet pipe in the corresponding storage coolant receptacle.3. Connect the pump to the pump power adapter and then power on.

What is the material of C2 kit?

The material of C2 tank is cold-rolled steel , the dry cooler is copper and aluminum fins.

If the C2 pump stops or reports an error, what will happen?

If the pump stops working, a “Pump Error” prompt will appear on our Tank’s display screen, accompanied by an alarm sound. If this situation is not addressed, the temperature of the coolant will continue to rise due to the inability to dissipate heat. Eventually, this will trigger the temperature protection mechanism of the mining rigs, causing them to stop operating automatically.

The material of C2 tank is cold-rolled steel , the dry cooler is copper and aluminum fins.

What should you do if there is high-frequency noise in the junction box when the fan is running at full speed?

In general, this issue might arise due to the loose fastening of screws on the internal PCB board of the junction box. You should dismantle the junction box and tighten the screws securely. If the screws cannot be tightened, you can try to replace the screws or add gaskets to tighten the screws (M3 screws and gaskets). If the problem persists, you can try to add gaskets (preferably rubber anti-vibration pads) at the bottom of the dry cooler to raise the fan to prevent noise caused by contact between the bottom of the dry cooler and the ground.

How to properly unload oil to avoid waste?

First, pump the oil out using the oil filling pump in the accessories. At the same time, there is an oil discharge port in the middle of the liquid separator plate at the bottom of the tank. After removing the screw, plug the oil filling pump in to clean up the liquid at the bottom of the liquid separator plate.

How does the oil filling pump work in accessories?

Instructions1. Connect the pump to the inlet and outlet pipes: Ensure a tight seal between the pipes and the pump to prevent low pressure or leakage. The arrow on the pump head indicates the direction of the outlet.2. Put the water inlet pipe below the coolant level, and put the water outlet pipe in the corresponding storage coolant receptacle.3. Connect the pump to the pump power adapter and then power on.

What is the material of C2 kit?

The material of C2 tank is cold-rolled steel , the dry cooler is copper and aluminum fins.

If the C2 pump stops or reports an error, what will happen?

If the pump stops working, a “Pump Error” prompt will appear on our Tank’s display screen, accompanied by an alarm sound. If this situation is not addressed, the temperature of the coolant will continue to rise due to the inability to dissipate heat. Eventually, this will trigger the temperature protection mechanism of the mining rigs, causing them to stop operating automatically.

If the pump stops working, a “Pump Error” prompt will appear on our Tank’s display screen, accompanied by an alarm sound. If this situation is not addressed, the temperature of the coolant will continue to rise due to the inability to dissipate heat. Eventually, this will trigger the temperature protection mechanism of the mining rigs, causing them to stop operating automatically.